Mission

The research activity of the MEDES group is aimed at the development of sustainable materials through the efficient use of resources; paying special attention to the use of non-conventional raw materials, such as industrial waste, as well as the application of concentrated solar energy to material synthesis and transformation processes. Namely:

– Ceramic construction materials (ceramic tile, porcelain stoneware, ceramic glazes, frits, bricks, etc.).

– Materials with new functionalities: absorbents (zeolites), fertilizers (glasses and lightweight aggregates) or decontaminants (glazes and ceramic tile).

– Recovery of industrial and mining waste and by-products as raw materials in the synthesis of ceramic materials.

Access to the group’s social networks:

Staff

Research Lines

Development of ceramic floor and wall tiles by vitrification of industrial waste

The MEDES Group has extensive experience in the application of sintering (ceramization) and vitrification technology for the valorization of industrial and mining waste. The MEDES group is considered a pioneer in this line of research, which began in the early 1990s. Through the ceramization process, waste is valorized as a secondary raw material in the formulation of fired clay bodies for construction materials (roof tiles, bricks, paving stones, rustic stoneware, etc.). Similarly, by means of the vitrification process it is possible to produce secondary raw materials useful in the manufacture of glassware, glass-ceramics and even porcelain stoneware, which are mainly used in flooring or wall coverings, both for outdoor and indoor use.

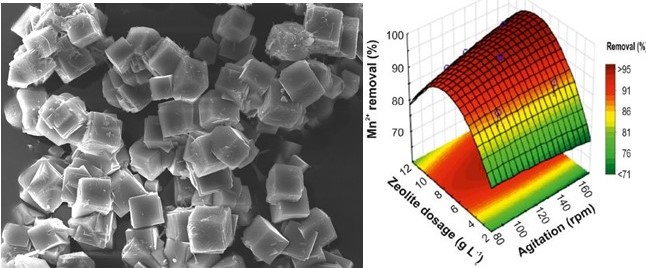

Synthesis of zeolite from industrial waste and their uses for removing heavy metals from aqueous effluents.

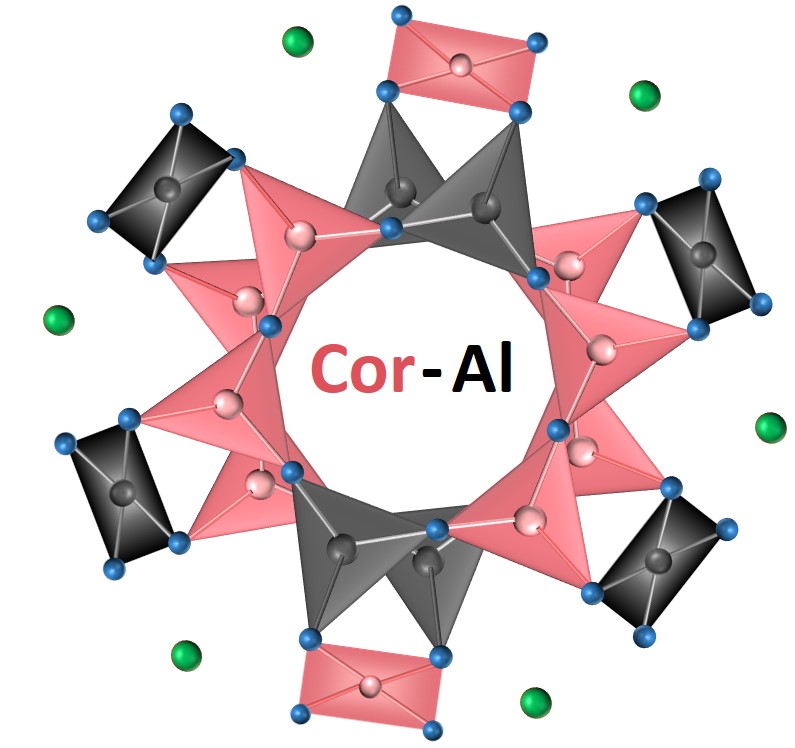

Zeolites are crystalline aluminosilicates with structures based on a three-dimensional network of AlO4 and SiO4 tetrahedra that are linked to each other through the sharing of their oxygen atoms. Their regular and uniform porous structures forming voids as channels, cages or cavities, infer them unique properties that allow the sorption and diffusion of ions and molecules. In this line, the activity developed by the MEDES group is focused on the synthesis of zeolites from hazardous waste and the use of these zeolites to the elimination of heavy metal such as, Pb, Cd, Hg, Mn, Fe, etc.

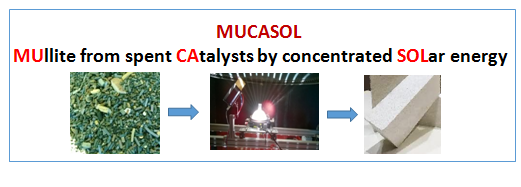

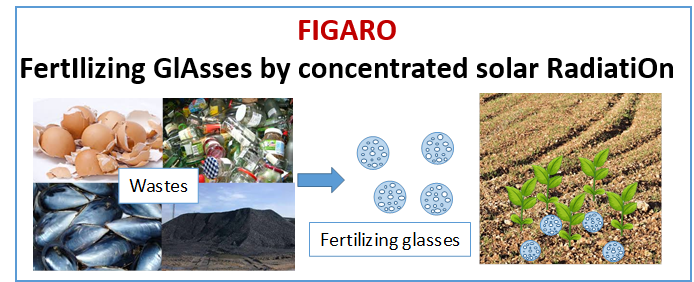

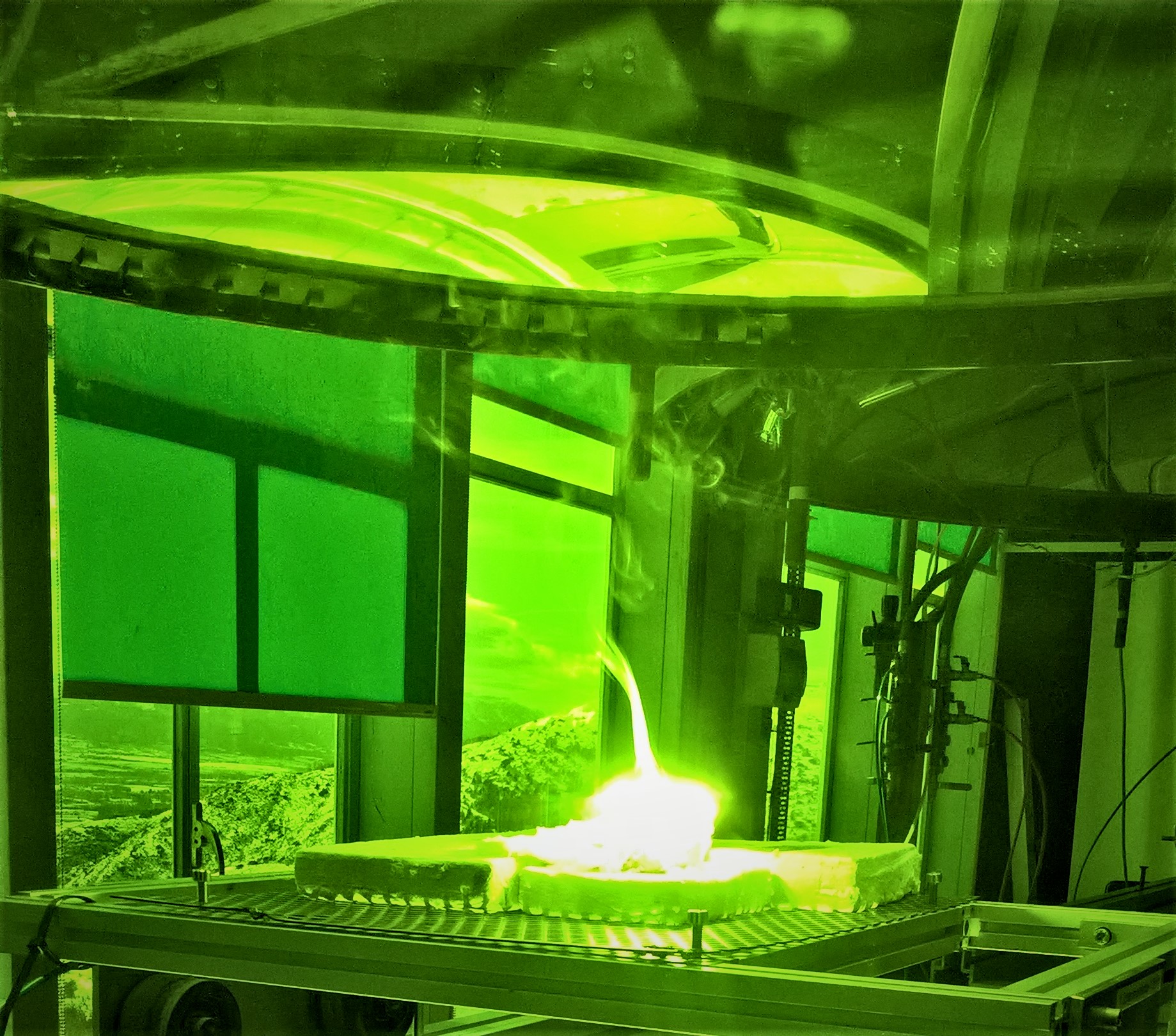

Application of concentrated solar energy (CSE) to materials synthesis processes

Concentrated solar energy (CSE) is one of the most promising renewable energies for its application to highly-demanding processes which allows performing high temperature material synthesis on the bases of efficient energy transformation. The MEDES group has extensive experience in the application of concentrated solar energy (CSE) to highly intensive energy processes, such as the manufacture of ceramic frits and glasses from different raw materials, the dehydration of gypsum and the preparation of alumina from boehmite, and also, the reduction to metal oxides.

Concentrated solar energy (CSE) is one of the most promising renewable energies for its application to highly-demanding processes which allows performing high temperature material synthesis on the bases of efficient energy transformation. The MEDES group has extensive experience in the application of concentrated solar energy (CSE) to highly intensive energy processes, such as the manufacture of ceramic frits and glasses from different raw materials, the dehydration of gypsum and the preparation of alumina from boehmite, and also, the reduction to metal oxides.

Design of frits for ceramic glazes with improved performance

Ceramic frits are essential raw materials in the preparation of glazes and engobes for the manufacture of glazed ceramic tiles. In recent decades there has been a notable improvement in the quality of life in different areas (housing, areas of social activity and work areas), which has stimulated the development of new building materials that interact with the environment. In this sense, glazed ceramic tile must also evolve to meet social demand. Glazing is no longer a material whose main function is to provide waterproofing and aesthetics, but rather to provide functionality to the ceramic tile. In this way, the glaze has come to interact with the environment and has become a living element with a specific function to improve the quality of life.

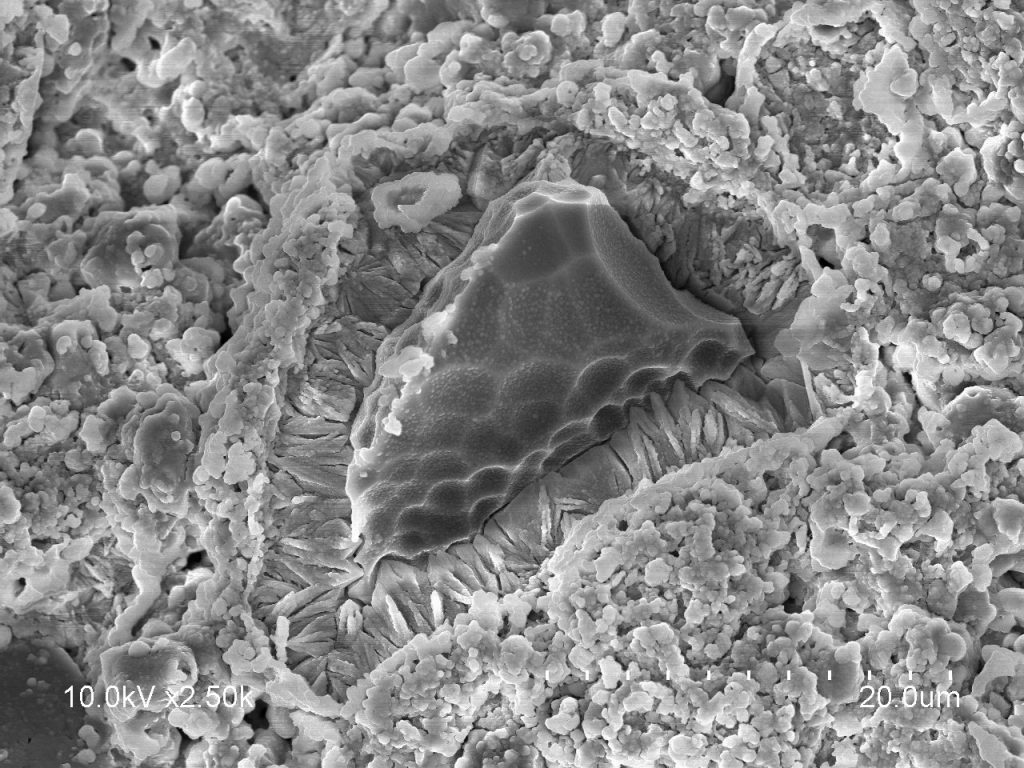

Synthesis and technological characterization of porcelain stoneware

Porcelain stoneware is a building material characterized by a compact microstructure and high technological properties, especially with regard to water absorption, chemical and frost resistance, resistance to bending and abrasion. Due to these properties, porcelain stoneware has been the material that has experienced the greatest increase in production and sales in recent years, among all ceramic building materials. In this line, the MEDES group has become an international reference in recent years, with numerous research projects that have deepened our knowledge of porcelain stoneware, mainly with regard to the crystallization kinetics of the mullite phase, the evolution of microstructure and mineralogy during the firing process of the pieces and the relationship between microstructure and technological properties of the fired tiles.

Porcelain stoneware is a building material characterized by a compact microstructure and high technological properties, especially with regard to water absorption, chemical and frost resistance, resistance to bending and abrasion. Due to these properties, porcelain stoneware has been the material that has experienced the greatest increase in production and sales in recent years, among all ceramic building materials. In this line, the MEDES group has become an international reference in recent years, with numerous research projects that have deepened our knowledge of porcelain stoneware, mainly with regard to the crystallization kinetics of the mullite phase, the evolution of microstructure and mineralogy during the firing process of the pieces and the relationship between microstructure and technological properties of the fired tiles.

Synthesis and technological characterization of fired clay ceramic materials

Throughout history, fired clay ceramic materials (paving stones, vaults, bricks, boards and tiles) have been present in the construction sector, evolving in parallel with the development of construction techniques. In this line, the activity developed by the MEDES group is mainly focused on the optimization of the design of the piece and its manufacturing process, the improvement of the technological properties and the study of the mechanisms that give rise to the appearance of different pathologies in the pieces (expansion due to humidity, efflorescence, frost resistance, etc.)

Physical and technological characterization of glass and ceramic materials from the Historical and Artistic Heritage.

The MEDES group belongs to the CSIC’s Thematic Network of Historical and Cultural Heritage. In this line, the group applies its knowledge and experience in chemical-physical characterization technique (SEM, TEM, XRD, XRF….) for the archaeometric characterization of glasses and ancient ceramic materials.

Facilities and resources

Processing techniques

- Automatic pressing of ceramic powder tablets, glass and its raw materials.

- Autoclave reactor

- Rotary evaporator

- Glass and frit melting furnaces (up to 1600°C).

- Annealing and heat treatment furnaces for nucleation and crystallization of glasses and frits and firing of raw ceramic samples or tablets.

- Magnetic separator.

- Ceramic slips applicator.

- Mills, mixers and sample dividers.

Characterization techniques

- Metallographic preparation of ceramic materials, glass and glass-ceramics

- Determination of ammonia by Kjeldahl method

- Leaching equipment

- Knoop and Vickers Microdurometer

- Equipment for measuring abrasion resistance (PEI method)

- Differential thermal and thermogravimetric analysis (DTA/TG) SETARAM Labsys

- Differential Scanning Calorimetry (DSC/TG) SETARAM Labsys

- Mechanical flexural and compression testing machine.

Metallographic preparation of glass, ceramic and glass-ceramic materials.

Scientific articles

Patents

Process for the valorisation of a waste from the grinding of aluminium slag

IETcc Inventors: A. López-Delgado, I. Padilla

Patent No: P201531811

Licensee: Alusigma S.A.

Date of licence: 11/10/2024

Method for obtaining vitreous lightweight aggregates

IETcc Inventors: M. Romero, A. López-Delgado, I. Padilla

Publication number: WO/2022/234173

Publication date: 10/11/2023

https://patentscope.wipo.int/search/en/detail.jsf?docId=WO2022234173&_cid=P21-LE8K3G-42986-48

Method and device for manufacturing glass frits

IETcc Inventors: M. Romero, A. López-Delgado

Publication number: WO2018162383

Publication date: 12/09/2018

https://patentscope.wipo.int/search/es/detail.jsf;jsessionid=03FF115E4D7FD771F90E01C2BBAF2D90.wapp1nA?docId=WO2018162383

Formación

Theses

Environmentally friendly solutions for the treatment of aqueous media containing textile dyes: Waste-based zeolites and bacterial biomass

Doctoral student: Magali Teresinha Ritter

Supervisors: María Ángeles Lobo Recio and Isabel Padilla Rodríguez

University: Universidad Autónoma de Madrid / Universidade Federal de Santa Catarina

Year: 2024 Grade: Excellent “Cum Laude”

International: Yes

Final Degree Projects

Evaluation of the adsorption properties of zeolites and its application in the design of a fixed bed for sulphur dioxide removal

Student: Claudia Barco Barona

Supervisor: Antonio Nieto-Márquez Ballesteros (UPM) y Rafael Carrizosa Muñoz (IETcc)

University: Universidad Politécnica de Madrid (UAM)

Faculty/School: School of Engineering and Industrial Design (ETSIDI). Bachelor’s Degree in Chemical Engineering

Year: 2024 Grade: 9.7/10

Valorisation of a catalyst residue from the petrochemical industry in the production of ceramic materials

Student: Rafael Carrizosa Muñoz

Supervisor: Maximina Romero Pérez

University: Universidad Autónoma de Madrid (UAM)

Faculty/School: Faculty of Science. Bachelor’s Degree in Chemistry

Year: 2023 Grade: 9.8/10

Curricular Internships

Conditioning and chemical characterisation of an aluminium salt slag

Student: Claudia Barco Barona

Supervisor: Isabel Padilla Rodríguez

University: Universidad Politécnica de Madrid (UPM)

Faculty/School: School of Industrial Engineering and Design. Degree in Chemical Engineering

Year: 2024 Grade: 10/10

Optimisation of the hydrolysis process of aluminium salt slag for the elimination of salts.

Student: Álvaro Sanz Sánchez

Supervisor: Aurora López Delgado

University: Universidad Complutense de Madrid (UCM)

Faculty/School: Faculty of Science. Bachelor’s Degree in Chemistry

Year: 2024 Grade: 8.6/10

Synthesis of mullite from catalyst waste from fuel hydrodesulphurisation

Student: Lucía Sánchez Ramiro

Supervisor: Maximina Romero Pérez

University: Universidad Complutense de Madrid (UCM)

Faculty/School: Faculty of Science. Bachelor’s Degree in Chemistry

Year: 2024 Grade: 7.6/10

Study of the aluminium slag hydrolysis process

Student: Jefferson Adrián Campoverde Buri

Supervisor: Isabel Padilla Rodríguez

University: Universidad Politécnica de Madrid (UPM)

Faculty/School: School of Forestry Engineering and Natural Environment. Degree in Environmental Technologies Engineering

Year: 2023 Grade: 9.55/10

Valorisation of catalyst residues in the synthesis of porcelain stoneware

Student: Pablo Valiente Vacas

Supervisor: Maximina Romero Pérez

University: Universidad de Alcalá de Henares (UAH)

Faculty/School: Faculty of Science. Bachelor’s Degree in Chemistry

Year: 2021 Grade: 9.5/10

Conditioning and chemical characterisation of an aluminium salt slag

Student: Claudia Barco Barona

Supervisor: Isabel Padilla Rodríguez

University: Universidad Politécnica de Madrid (UPM)

Faculty/School: School of Industrial Engineering and Design. Degree in Chemical Engineering

Year: 2024 Grade: 10/10

Optimisation of the hydrolysis process of aluminium salt slag for the elimination of salts.

Student: Álvaro Sanz Sánchez

Supervisor: Aurora López Delgado

University: Universidad Complutense de Madrid (UCM)

Faculty/School: Faculty of Science. Bachelor’s Degree in Chemistry

Year: 2024 Grade: 8.6/10

Synthesis of mullite from catalyst waste from fuel hydrodesulphurisation

Student: Lucía Sánchez Ramiro

Supervisor: Maximina Romero Pérez

University: Universidad Complutense de Madrid (UCM)

Faculty/School: Faculty of Science. Bachelor’s Degree in Chemistry

Year: 2024 Grade: 7.6/10

Study of the aluminium slag hydrolysis process

Student: Jefferson Adrián Campoverde Buri

Supervisor: Isabel Padilla Rodríguez

University: Universidad Politécnica de Madrid (UPM)

Faculty/School: School of Forestry Engineering and Natural Environment. Degree in Environmental Technologies Engineering

Year: 2023 Grade: 9.55/10

Valorisation of catalyst residues in the synthesis of porcelain stoneware

Student: Pablo Valiente Vacas

Supervisor: Maximina Romero Pérez

University: Universidad de Alcalá de Henares (UAH)

Faculty/School: Faculty of Science. Bachelor’s Degree in Chemistry

Year: 2021 Grade: 9.5/10