The Facilities Laboratory has always worked under different names, giving internal support to the Institute itself and above all external support to different industries and entities.

Currently it has an infrastructure that allows it to address a wide range of issues within the sector of systems, elements and materials, related to the building installations in even some of the civil works.

On 21-12-2018 the accreditation by the National Accreditation Entity ENAC in accordance with the UNE-EN ISO/IEC 17025 standard. This standard contains requirements to enable laboratories to demonstrate that they operate in a competent manner and have the capacity to generate valid results.

The facilities laboratory has accredited 13 test methods defined in technical annex no. 1194/LE2284, in two different areas: construction elements and building envelopes and their accessories; and plastic and composite materials.

The following tables indicate the 13 testing methods for which accreditation has been achieved:

Area of construction elements and building enclosures and their accessories

| Product/Material to be tested | Essay | Norm / Essay Procedure |

|---|---|---|

| Thermal insulating products | Compression behaviour (F<48kN) | UNE-EN 826 |

| Modulus of elasticity | UNE-EN 826 | |

| Tensile strength perpendicular to faces (F<48kN) | UNE-EN 1607 | |

| Tensile E-modulus of the core (Ect) | UNE-EN 14509 | |

| Determination of apparent density of the core | UNE-EN 1602 | |

| Self-supporting double skin metal faced insulating panels | Resistance to shear test on the core material (fcv) (F<48kN) | UNE-EN 14509 |

| Thermal performance of building materials and products (Products of high and medium thermal resistance.) | Thermal conductivity by means heat flow meter methods λ= (0,02 – 0,35) W/(m.K) | UNE-EN 12667 |

Área de materiales plásticos y materiales compuestos

| Product/Material to be tested | Essay | Norm / Essay Procedure |

|---|---|---|

| Thermoplastics pipes and fittings | Resistance to internal pressure

Water in air: 110 °C |

UNE-EN ISO 1167-1 UNE-EN ISO 1167-2 |

| Thermoplastics pipes | Ring stiffness dn ≤ 800 mm F < 48kN |

UNE-EN ISO 9969 |

| Plastics piping systems. glass-reinforced thermosetting plastics (GRP) pipes | Initial specific ring stiffness (Method B (Constant deflection) dn ≤ 800 mm F < 48kN |

UNE-EN 1228 ISO 7685 |

| Initial ring deflection dn ≤ 800 mm F < 48kN |

ISO 10466 | |

| Initial longitudinal tensile strength (Method A (strip test piece)) dn ≤ 800 mm F < 48kN |

UNE-EN 1393 ISO 8513 |

|

| Apparent initial circumferential tensile strength (Method B (split disc test)) dn ≤ 800 mm y F <48 kN |

UNE-EN 1394 ISO 8521 |

Out of the scope of the accreditation and with the same rigor, they also carry out different types of tests to all types of plastic conducts, systems and accessories for the conduction of pressurized water, evacuation and sanitation, A.C.S. systems, sectioning valves, sandwich panels, thermal insulators, etc, both under standard and according to the design of the petitioner. As well as the elaboration of different Technical Suitability Documents (TSD) in different fields

Infrastructures

It has two buildings in which different works are carried out, in one of them most of the functional tests are centralized and in the other one the shock tests and long term thermal cycles.

It has the collaboration of other laboratories with which it works and collaborates jointly in multidisciplinary work, such as the Physical-Chemical Analysis Laboratory for the characterisation of materials from the micro to nanometric perspective, the Mechanical Testing Laboratory for carrying out large-scale tests capable of undertaking work on a real scale with sizes of a few metres and large loads, the Acoustics and Radon Laboratory where acoustic tests can be carried out, and the DIT Laboratory for other tests related to obtaining the Technical Suitability Document, which also has UNE-EN ISO 9001:2015 Certification.

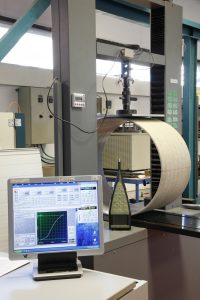

Equipment

It has sufficient means to carry out the work entrusted to it with a wide spectrum and versatility so that requests for non-conventional tasks can be met and which other laboratories do not usually carry out due to their uniqueness, so that tests are carried out under specific design in accordance with the requestor.

A sample of some of the equipment, test benches and tools may be:

- 2 tonne overhead crane

- Universal mechanical test press up to 5 t. With several load cells from 50 N and different types of displacement sensors, included for longitudinal and transversal deformation calculations. The press has a computer system with which it is possible to carry out tests implemented by the UNE-EN standard and design any other type of customised test. All its components are calibrated by laboratories with ENAC accreditation for this purpose.

- Dimensional magnitude gauges, calipers, mechanical and ultrasonic thickness gauges, internal diameter gauges, with different accuracies from 10 um.

- All types of auxiliary supports for mechanical tests, such as supports for bending and three- or four-point shear tests, mechanical and magnetic anchoring systems, etc.

- Thermal chamber that can be attached to the press to carry out tests under different thermal conditions between -30ºC and +200ºC, with an internal space of 300x300x300 mm.

- Hydraulic pressure testing machine, with 30 independent outlets for simultaneous tests from 0 to 100 bar, controlled by a computer and a software application in which all types of ramp, cyclic and programmed tests can be carried out. This machine is also independently calibrated in each of its intakes by a specialized laboratory with ENAC accreditation.

- Seven baths or tanks all equipped to achieve different water temperatures containing from 10 ºC to 100 ºC thermally controlled, five of them coordinated with the previous hydraulic pressure testing machine with direct connections between them, which guarantees the performance of tests at any pressure and temperature within the indicated ranges.

- Hydraulic pressure and pneumatic vacuum testing machine, for low pressures of 0.05 to 0.5 bar

- Test bench that can be coupled to the previous machine for testing pipe connections subject to angular deviation without axial stress.

- Vacuum pumps for negative pressure testing.

- All types of caps, plugs, valves, connections and hoses resistant to high pressures (up to 100 bar) for testing pipes of different diameters up to 500 mm at high pressure and up to 1200 mm at low pressure.

- Tests are carried out on isolating valves, especially gate valves according to the UNE-EN 1074-1-2:2001 and UNE-EN 12266-1-2:2003 standards, in which all types of sealing and internal pressure resistance tests can be performed, including mechanical fatigue resistance.

- Two machines to obtain the thermal conductivity coefficient of insulators (from 0.3 to 0.002 (W/m.K) for 300×300 mm and 600×600 mm specimens.

- Thermal fatigue test bench for panels up to 8 meters UNE 41950

- Thermal shock test benches UNE-EN 1055 and temperature cycles UNE-EN 12293:2000.

- Three stoves of 800x800x500 mm up to 150 ºC

- Several data acquisition systems for recording long-term test parameters.

- Several scales of different ranges from 0 to 250 g of 4 digits to 0 to 150 kg of 1g.

- Various equipment and probes for temperature measurement.

- And auxiliary material and tools that allow the realization of the tests that are the object of the Laboratory.

- The manufacturers and brands of the equipment indicated are among the most prestigious and top lines, both European and national, within their sector.

Activities and work of the Laboratory

As already mentioned, this Laboratory is dedicated to a great diversity of activities, studies and tests, within the field of Building and Civil Works, especially on materials, elements and systems related to installations.

Since it is a living laboratory that is at the service of the demand of researchers and industry, its activity is based on the capacity to undertake a great versatility of work.

However, due to a greater demand lately, it has specialized in pipes and accessories in charge of water conduction, so it carries out all kinds of tests on watertightness and resistance to internal hydraulic pressure, as well as tests on isolating valves required by the UNE-EN 1074 standard.

For this reason, it carries out this type of test for several manufacturers of ductile iron sectioning valves that require this type of test to enter the Canal de Isabel II tender, thanks to which it has acquired a great deal of experience in carrying out these tests.

In addition, it carries out all kinds of hydraulic tests on mainly plastic pipes for many prestigious manufacturers of pipes and accessories, becoming regular customers.

In addition to the activities described in the hydraulic sector, it carries out concession and monitoring tests for AENOR quality mark certification for different manufacturers of thermal insulating sandwich panels, for which it is the first laboratory recommended in AENOR’s Special Regulation 020 for carrying out these tests.

It intervenes in technical reports for legal disputes between parties, attending trials as technical experts by summoning the judge or the parties as experts.

The experience of the Laboratory allows its technicians to participate in knowledge transfer activities, such as the production of scientific articles and attendance at congresses presenting the knowledge obtained from this experience.

Carrying out intercomparisons between laboratories, by way of example this year three intercomparisons have been carried out with the Facilities Laboratory acting as organiser and leader with great success, achieving the participation of a large number of the most emblematic laboratories on the Iberian Peninsula. One on water pipes with the participation of 17 laboratories and the other on thermal insulation with 11, all the most recognized, both private accredited, universities and manufacturers.

Some of the standards with which tests are carried out in the Laboratory:

UNE-EN 826 Thermal insulation products. Resistance and modulus of elasticity to compression

UNE-EN 1607 Thermal insulation products. Tensile strength perpendicular to faces

UNE-EN 14509 Thermal insulation products. E-module of core traction

UNE-EN 1602 Thermal insulation products. Apparent density of the core

UNE-EN 14509 Thermal insulation products. Resistance to shear stress on core material

UNE-EN 12667 Construction materials (Products of high and medium thermal resistance). Thermal conductivity by the Heat Flow Meter method

UNE-EN ISO 1167-1 y 2 Plastic pipes and accessories. Internal pressure resistance.

UNE-EN ISO 9969 Thermoplastic pipes. Annular rigidity.

UNE-EN 1228 e ISO 7685 Glass fibre reinforced thermoset plastic tubes (GRP). Initial specific circumferential rigidity (Method B (constant deflection)

ISO 10466 Glass fibre reinforced thermoset plastic tubes (GRP). Initial circumferential deflection

UNE-EN 1393 and ISO 8513 Glass fibre reinforced thermoset plastic tubes (GRP). Initial resistance to longitudinal traction

UNE-EN 1394 and ISO 8521 Glass fibre reinforced thermoset plastic tubes (GRP). Apparent initial circumferential tensile strength (method B (semi-disk test))

UNE-EN 1055:1996 Plastic piping systems. Thermoplastic ducting systems for the evacuation of waste water inside the building. Test method for cyclic resistance at high temperature.

UNE-EN 1074-1-2 Valves for water supply Requirements for fitness for use and verification tests.

UNE-EN 1253-1-2-3-4-5 Drains and siphons for buildings.

UNE-EN 1329-1 System of channelling in plastic materials for the evacuation of waste water (low and high Tª) within the structure of buildings. Non-plasticized poly (vinyl chloride). (PVC-U).

UNE-EN 1401-1 Drainage system in plastic materials for underground sanitation without pressure. Unplasticised poly (vinyl chloride) (PVC-U).

UNE-EN 1452-1-2 Plastic piping system for water supply and for underground or above-ground drainage with pressure. Unplasticized poly (vinyl chloride) (PVC-U).

UNE-EN 1453-1 Plastic piping system with structured wall pipes for the evacuation of waste water (at low and high temperature) inside the building structure. Unplasticised poly (vinyl chloride) (PVC-U).

UNE-EN ISO 3994 Plastic-based hoses. Hoses made of thermoplastic materials with helical thermoplastic reinforcement for suction and discharge of aqueous materials. Specifications

UNE-EN ISO 9967 Thermoplastic material tubes. Determination of creep.

UNE-EN 12293 Trunking systems in plastic materials. Thermoplastic pipes and accessories for hot and cold water. Test method to determine the resistance of couplings to temperature cycles.

UNE-EN 13476-1-2 Drainage system in plastic materials for non-pressure underground drainage and sanitation. Structured wall ducting system made of unplasticised poly (vinyl chloride) (PVC-U), polypropylene (PP) and polyethylene (PE).

UNE-EN 14509 Self-supporting double-sided metal sandwich panels. Factory-made products. Specifications

Quality

The Laboratory of Facilities, is accredited by ENAC from 21-12-2018 in 13 techniques of test.

It has its own Quality Management System, with a person in charge who is exclusively responsible for its management. The Laboratory has its Quality Manual and Quality Operating Procedures (QOPs) and Standard Operating Procedures (SOPs). In addition, as a consultancy, it uses a quality management systems consultancy company with which it has had a contractual relationship during accreditation, which serves as support in this type of issue.

Most of the tests performed by the Laboratory are carried out in accordance with the UNE-EN, UNE-EN ISO, EN, or any other type of product and test method standards.

However, tests are also performed under the specific design and request of the applicant, although standardized or self-validated test methods are applied

Differentiating elements

The Instituto Eduardo Torroja, and therefore the Facilities Laboratory, depends on the state agency Consejo Superior de Investigaciones Científicas (CSIC), which has no links with private companies and entities, which gives it one of its clearest differentiating elements, its independence.

The Facilities Laboratory, as it is located within an Institute dedicated to Scientific and Technological Research, has the most up-to-date information regarding both the latest technical advances and the latest legislative provisions that may affect the sector, proof of which is that the CTE Spanish Building Code is drawn up at the Institute itself.

The Instituto Eduardo Torroja, in accordance with Decree No. 3652 of 26 December 1963 and the Ministerial Order of 23 December 1988, and Order CTE/2276/2002, of 4 September, is the entity that grants the DIT National Technical Approval, which contains a technical assessment of the suitability for use in building and/or civil works of a given innovative non-traditional building material, system or procedure. The DIT is recognized worldwide, especially in Europe and Latin America.

The Institute is a member of the UEAtc (Union Européenne pour l’Agrément Technique dans la Construction) which is the organization that brings together the Institutes representing 16 European countries, recognized by their respective governments, for the granting of the ITL. The Facilities Laboratory, and its technicians as speakers, produce ITLs, for which they are recognized.

The Institute is on the list of Notified Bodies by the Ministry of Development and Industry with No. 1219, capable of certifying construction products with Conformity Assessment System 1, for the granting of DITs.

The Institute enjoys a recognized prestige and reliability that has provided the knowledge and experience of its technicians and facilities by resorting to their impartial advice in legal disputes. By extension, its Facilities Laboratory has been claimed through its technicians on many occasions as experts in various cases.

In addition, the Facilities Laboratory belongs to the Network of Laboratories and Infrastructures of the Directorate General of Universities and Research of the Autonomous Community of Madrid with the number 153. (http://www.madrimasd.org/laboratorios/documentos/red-laboratorios/documentos/catalogo.pdf) with the category of Documented Procedures: These are the laboratories that, in addition to ensuring compliance with the technical requirements of Level 2 laboratories (under review to be updated after ENAC accreditation), have documented procedures or standards for the provision of service to customers.

The Laboratory has extensive experience in the preparation of technical reports on the quality and self-control tests for the manufacture of products in order to comply with the requirements of the application for quality certificates from AENOR or other certification bodies, or to take part in tenders from different bodies such as state civil engineering joint ventures, water suppliers, etc