Mission

The main goals of the Research Group is to generate knowledge and to develop new technologies in the field of construction materials and particularly in durability of cement-based materials.

The Research Group has a multidisciplinary profile that allows us to carry out basic research with the development of mechanisms as well as to applied research with the development of products in conjunction with big companies.

Staff

Research Areas

- Study of corrosion mechanisms using electrochemical techniques.

- Non-destructive tests (NDTs) for the quantification of corrosion and the useful life of reinforced concrete structures.

- Stress corrosion cracking and hydrogen embrittlement of high strength steels.

- Durability of concrete.

- Quality control of concrete using in-situ non-destructive techniques.

- Assessment of reinforced concrete structures.

- Monitoring of structures: corrosion, environmental and mechanical sensors, etc.

- Development of non-contact corrosion rate methods.

- Study and monitoring of innovative repair solutions: surface inhibitors, cathodic protection, stainless steel and galvanized steel, etc.

- Multi-physics and multi-scale simulation: from the atom to the structure.

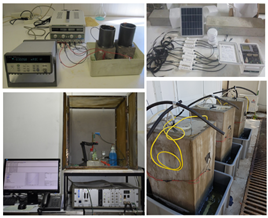

Facilities and resources

The Research Group manages three laboratories with the following means:

- Equipment for carrying out durability tests according to current regulations in:

- Water absorption by Fagerlund method,

- Oxygen permeability,

- Chloride ion diffusion by natural and accelerated method,

- Direct and indirect electrical resistivity,

- Natural and accelerated carbonation tests,

- Alkali-silica reaction in concrete.

- Equipment for the design of new test methods related to the durability of concrete.

- Electrochemical equipment.

- Portable corrosion devices Gecor-10 and Gecor-08.

- Potentiometric titrator for elemental analysis.

- Portable X-ray Fluorescence equipment.

- Universal mechanical testing machine with electrochemical cell.

- Controlled atmosphere tests.

- Laser scanner.

- Access to cluster facilities.