- Financing entity

- EU, 7th Framework Programme (SFERA 3 Programme)

- Duration

- 2022-2024

- Principal investigator(s)

- Aurora López-Delgado

- Budget

- Official web

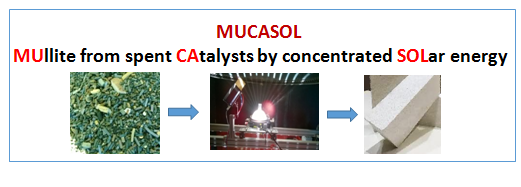

Mullite (3Al2O3·2SiO2) is an aluminosilicate endowed with excellent physico-chemical properties such as: high temperature resistance, thermal shock resistance and also good resistance to wear and deformation. Due to these characteristics, mullite has become a choice of material for advanced structural and functional ceramics. It is used extensively in traditional refractory applications.

Mullite rarely occurs in nature, so it is usually synthesized, rather than mined. Various preparation methods and starting materials are used for the synthesis of mullite ceramics. Nevertheless the synthesis of mullite is highly expensive due to the cost of both the raw materials, which must be synthesized or mined beforehand, and the energy consumed to achieve the high temperature (1400-2000 ºC) required.

In this project, we study the synthesis of mullite from spent catalysts, specifically those from one of the most important catalytic processes such as crude oil hydrodesulphurisation, which is aimed to remove sulphur- nitrogen- and oxygen-containing compounds. In this sense, the catalyst most commonly employed is molybdenum with nickel (Ni-Mo catalyst) or cobalt (Co-Mo catalyst) promoters, supported on alumina or alumina/silica. The world consumption of catalyst petroleum refining is estimated to be 440,000t/year. After its use, the catalyst is subjected to several recycling cycles, but at the end of its life it is considered by EPA as hazardous waste.